How great would it be if you could control that and make it happen anytime you want? So, a few years ago, I learned about Tesla Coils, an air core electrical resonant transformer, invented by Nikola Tesla at the end of the XIX century, able to generate high voltages at high frequencies, resulting in electrical discharges just like small lightning. From that moment I knew I had to build my own Tesla Coil.

Back in 2010, I started to seriously think about it, plus, one of my University teachers was encouraging me on making one, so I got together with two great friends of mine, Micael Martins and Jarred Briscoe, and we started planning it.

First things first, what type of Tesla Coil should we build? There are many different variations: first you have the Spark Gap Tesla Coils or SGTC, as the name says, these are based on a spark gap switching mechanism, they are more simple to build but require a high voltage power supply; then there are the Solid State Tesla Coils or SSTC which rely on transistors such as MOSFETs or IGBTs to handle the switching part, these are the ones that can be turned into musical Tesla Coils, however they might be quite complex to design; and then there are others like the Vacuum Tube Tesla Coils or VTTC which use the good old vacuum tubes as a mean of generating the oscillation needed for the circuit.

Since this was our first one we thought it was a good idea to choose something simple and cheap, so we opted for the spark gap Tesla Coil. There are some different variations of the schematic but we will follow this simple one:

Probably the most expensive and hardest part to find, is the high voltage power supply, which is also the most important one, because ultimately, the maximum spark length you can generate is directly related to the power of the supply. The most common choice here is a Neon Sign Transformer also known as NST, because of their low size and weight compared to other alternatives like the pole pig oily transformers for example, which are extremely big and heavy, and are harder to obtain. The power transformer should have a voltage between 9kV and 15kV.

For us this part was easy because I already had a NST laying around at home from an old neon sign. This transformer we're using has 10kV and 30mA:

Next, with the characteristics of the transformer, it must be determined the value of the primary tank capacitor. Every half cycle of the mains supply, in my case every 10 ms since the frequency in Portugal is 50Hz, the spark gap will fire and transfer the energy from the primary capacitor to the primary coil, which means that the capacitor must be able to fully recharge every half cycle as well. So the appropriated capacity must be calculated.

Using Ohm's law for alternate current with the transformer specifications we get:

The value for the primary capacitor must be close to 9.5 nF. Now there are several ways to get a capacitor for the circuit, but it must be able to support the high voltage generated by the transformer, in this case 10kV. An option would be to buy one, but it might be really hard to find one with the exact same capacity you need and with the necessary voltage. The other option is to build one, and there are many ways you can make your own capacitor. The most usual is making an MMC or Multi Mini Capacitor out of smaller capacitors associated in series and parallel until you reach the values for capacity and voltage you need, this is usually the preferred choice by makers.

When I started checking prices for smaller capacitors I discovered that even if they weren't expensive, it would still cost me around 100€ because I would be needing a lot of them. But that was unacceptable for me, I was aiming for something cheap so I couldn't spend all that money just for the capacitor.

So I started looking for alternatives, then I figured, since I won't buy a capacitor, I can build it completely from scratch. Again, there are always different options, in this case, there are 2 easy ways of building a capacitor from raw materials. One way is using intercalated layers of a conductive material and an isolator, which is known as a plate capacitor. The other way is using the principle of the Leyden Jar, the original form of the capacitor, which can be easily reproduced with glass bottles. We eventually chose the second option and started making a bottle capacitor.

All we needed was a plastic bucket (avoid black plastic because they can have conductive properties), glass bottles, water, salt, oil (mineral is preferred but vegetable also works, although it might be starting to smell like fries), a few wires, hex bolts and nuts.

We heated up the water, started pouring salt and mixing it until it reached the saturation point, this is, until it couldn't dissolve salt anymore. The salt water will be the conductive electrode for both sides of the capacitor, the salt is added to make sure the water is highly conductive, and the heating is just to speed up the process of dissolving the salt. Then the salty water is poured inside the glass bottles until a certain point. The rest of the bottle is filled up with oil like it shows in the following image:

The purpose of the oil is just to serve as an electric insulator to avoid arcs inside the capacitor. The area inside the bottle where the water is in contact with the glass will be one of the conductive electrodes. The bottles will be later put inside the bucket and the bucket filled with the same mixture at the same levels:

To have an idea of how many bottles you'll need, you can consider that a normal 330 ml bottle will give about 1nF of capacity, depending of course, on the water/oil proportion you'll put in. Since I'm aiming at 9.5 nF, this means I'll probably be needing something like 9 to 10 bottles, but this is always a rough estimate, so you better have more bottles ready.

But I wanted to make sure of it, so I started calculating. For this you'll need the formula for capacitance, which relates the electric capacity with the area of the electrode plates, the distance between them, and the vacuum and relative permittivity. The vacuum permittivity is a constant equal to 8.854x10^-12 but the relative permittivity varies with the dielectric material. Usually for glass, this value is somewhere between 3.7 and 10. For the bottles I was using I was able to determine, through some practical experiments, that the relative permittivity was approximately 9. But there are many data tables you can use for reference.

First you need to calculate the area of electrode, which can be calculated by multiplying the perimeter of the bottle by the height of the water inside:

Now, considering the thickness of the glass bottle to be approximately 2mm, we can apply the capacitance formula:

As you can see, the capacitance of a single bottle is almost 1 nF, but not exactly. Since we need 9.5 nF, all we have to do now, is to determine how many bottles it'll take to reach the value we want:

In this case, I'll need 11 bottles to make a capacitor with 9.5 nF. But remember, although this is the correct calculation, this is just a theoretic approach, which means that in practicality, things might not be as certain. There are many details which might bring errors into the equation, like the level of the water not being the exactly the same in all bottles, differences in the glass itself, the saturation of the water decaying over time, among others. For these reasons, it's always a good idea to leave a few more bottles as a reserve, in case you still need a bit more capacitance in the future. It makes no difference if they are left inside the solution, as long as they are not connected with jumper wires. In my case, I discovered that after a few months, the water lost concentration and the total capacity had decreased. I shook the capacitor a little bit to mix the salt with the water and it worked, but with years passing by, water also tends to evaporate, decreasing the level, therefore the area of the electrodes and ultimately, the capacity itself. In this case is useful to have extra bottles ready, then all you have to do is to add an extra jumper wire to one of theses extra bottles.

Here are the bottles with the solution, ready to be put inside the bucket:

Even though we only needed 11, we added an extra one for the future. We tighten them together with zip-ties and placed them inside the bucket. Then filled the bucket also with salt water until it reached the same level as the water inside the bottles. And finally, filled the rest with oil. We drilled the lid of the bucket to put 2 hex bolts, which would serve as the 2 terminals, and then connected 11 of the 12 bottles with the jumper wires. The inside of the bottles connected to one of the bolts, and the wire left in the outside of the bottles connected to the other bolt:

After this, our primary tank capacitor is ready. With the help of an LCR meter we were able to confirm the final value of our home-made capacitor. And it turned out to be quite a surprise, since the value was quite close to our calculations, the LCR meter read 9.45nF, which was quite impressive. This is the final aspect of the capacitor:

Now let's move to the simplest but still very important part of the circuit, the spark gap. Like I explained before, the spark gap represents the switching mechanism that forces the capacitor to transfer its energy to the primary coil. A spark gap is basically a device that uses the air to conduct electricity. There are a few types of spark gaps, from simple and static ones, to rotary and speed controllable spark gaps.

Again, since we were aiming at a simple and cheap project, we opted for the static gap. Usually they are separated into smaller air gaps all connected in series, which has the advantage of supporting more power, since it can dissipate more heat, and also allows for easier tuning when adjusting the distance between the electrodes, because it becomes a matter of choosing to which electrode the connection is made. Sometimes a ventilation system is also added to the spark gap, to help reduce the heating.

Considering that we wanted something simple but effective, we decided to use a single air gap, besides, our transformer was not that powerful, and since we would be using bolts as electrodes, they would be able to dissipate the heat fairly well, even without ventilation. The distance between the electrodes would also be easy to adjust because we were using bolts, so by rotating a bit more or less, would also vary the distance as well. The usual distance is around 6 mm for a 10 kV NST.

Here is our simple spark gap:

And with this, the primary circuit is almost finished, the primary coil is the only part missing, but to be able to design this coil properly, we must first design the entire secondary circuit, which is composed by the secondary coil and the discharge terminal.

First let's focus on the secondary coil. The most common material for this part is a PVC pipe, fortunately I already had a few of these at home:

Now comes the incredibly annoying part, winding the secondary coil. This will be a time consuming task if you don't have any automated way of doing it. We had access to a winding machine but it was not prepared to handle such a long coil, so we ended up winding it by hand.

We used a PVC pipe with an 80 mm diameter and a length a bit smaller than 1 m. We used a 0.72 mm copper wire and winded up around 840 turns, so the coil itself had a length of 605 mm. This means we used about 211 m of copper wire:

Now we need to know the inductance of the coil in order to later determine the resonant frequency of the secondary circuit. For this we can use the inductance formula for cylindrical coils:

We will also need the self capacitance of the secondary coil, but this is a bit harder to calculate. The fastest way would be to use the LCR meter again, and since we're using it, we can confirm if our inductance calculation was correct.

For our coil, the LCR meter showed an inductance of 7.48 mH, again, remarkably close to the theoretic approach, and a self capacitance of 8.35 pF.

And now the discharge terminal. There are 2 commonly used shapes for this part, a sphere and a torus or toroid. This terminal acts as a capacitor, and together with the previous coil, they form the secondary LC circuit. There are not many guidelines when building this part of the project, but basically the bigger it is, the more capacitance it will have.

For this we used 2 metal discs, a threaded rod, aluminium ducting, nuts and aluminium tape:

The discs are drilled in the centre to pass the threaded rod. A U shaped support is placed underneath one of the discs, it will serve as a base to grab onto the PVC pipe of the secondary coil. Then the aluminium duct is placed on top of this disc:

The other disc is then placed on top of the aluminium duct and tighten with a nut:

To determine the self capacitance of a toroid, the following formula can be used:

The result comes in pico Farads.

Now that we have the secondary coil and the toroid, the secondary circuit is complete. This is actually an LC circuit, so it will have a resonant frequency:

A Tesla Coil is a resonant transformer, which means, that the best and most efficient energy transfer will occur when both the primary and secondary resonant frequencies are the same.

The resonant frequency of an LC circuit is given by:

The secondary LC circuit has a resonant frequency of approximately 355.2 kHz. Now it's time to go back to the primary circuit and determine the inductance of the primary coil. The primary circuit is also an LC circuit when the spark gap fires:

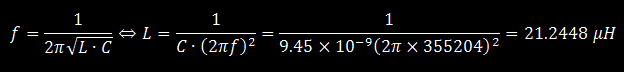

And it must have the same resonant frequency of 355.2 kHz. We already have the capacitor, which has 9.45 nF, so we can obtain the inductance with the same formula:

We conclude that the primary coil needs to have an inductance of 21.2448 μH to assure that both the primary and secondary circuits have the same frequency.

The primary coil is a good place for fine tuning the Tesla Coil after its construction is complete. No matter how many calculations have been made, there will always be differences from what you've designed and what you've ultimately built. For this reason it is a good idea to make sure the primary coil will have some extra turns, in case the math is a little off.

To do this, you'll need to try some different values. In my case, I'm using a 6.5 mm copper tubing, the inner diameter of the coil will be around 115 mm, and the spacing between turns is also 6.5 mm:

With these parameters I have enough space and copper to make about 11 turns. Now there are a few different formulas you can use for calculating a flat spiral coil, most of them use the width of the coil (w in the previous figure) and the mean radius (r), which can be both calculated through the other distances I already have.

First, the width of the coil:

Then comes the mean radius:

And ultimately the coil's inductance:

This formula returns the value in μH.

By using 11 turns with these characteristics, the primary coil will have a total of 30.1938 μH, well above the 21.2448 μH needed to generate the resonant frequency. This should be more than enough to adjust any discrepancies that may occur.

However, I need to know exactly in which turn I'll have the inductance I want, to place the outer terminal of the coil. To do this I must recalculate the coil by testing with a different number of turns, until it reaches values close to 21 μH. To assist with these repetitive calculations I created a spreadsheet with all these formulas to automate the process. Another option is going to the website DeepFriedNeon, which has a few good online calculators you can use, for all the parts of a Tesla Coil, as well as some construction guidelines. It's particularly useful for the primary coil.

By testing with a different number of turns, I can observe that if I use 9, I will obtain 19.25 μH and if I use 10 turns I will get 24.34 μH, this means that the value of 21.2448 μH which I need for the resonant frequency, is somewhere between turn 9 and 10 of my primary coil.

To build the flat coil we used 6.5 mm diameter copper tubing and some PVC U profiles. We drilled a series of 7 mm holes for the copper tubing, onto the PVC profiles, they would be the support of the coil. The copper tubing was then guided through these holes. Here is the final result:

Using the LCR meter again we were able to determine that the primary coil had a total of 28.6 μH, which is close to 30 μH but still different, probably due to construction imperfections.

With the primary coil finished, it was time to start building the main structure for the Tesla Coil. For this we used 2 pieces of wood to create 2 bases on top of each other, one bellow for the NST transformer and the spark gap, and one on the top for the primary and secondary coil.

4 threaded rods were used to connect the 2 bases of the structure. The rods were also put inside small PVC pipes for safety, to add insulation in case of an accidental discharge towards them.

The primary coil was then fixed onto the top base:

Next, we cut a small acrylic with the same size of the base and added the holes for the secondary coil and the threaded rods. Besides aesthetics, this should help prevent discharges onto the primary coil, therefore protecting the NST. Then the secondary coil was mounted onto the structure:

The toroid was fixed onto the PVC pipe and the top terminal of the secondary coil was connected to the base of the toroid. Here is how it looks so far:

The NST transformer and the spark gap were then placed on the bottom base:

Additionally, 2 filters can be used. One of them in the mains supply, to avoid high voltage kickbacks from reaching your house's wiring, which is basically an AC filter, and it can also have a capacitor bank to help correct the power factor of the circuit. And another filter after the NST, usually known as Terry filter which helps protect the transformer from over voltages and high RF feedback.

I have neither of these filters, however, since I needed a connector for the mains supply and I used one from an old ATX power supply, it already had a small filter integrated. It is not exactly dimensioned for this application, but I thought it wouldn't hurt to have it on the circuit. Still better than nothing:

Although the earth is connected to the white wire, this is left unconnected on the other side of the cable.

Now the other connections. The mains supply come through this AC filter and then goes directly to the primary of the NST transformer.

After the NST, all wiring mush be made with high voltage cables. The high voltage output from the NST is connected in parallel with the spark gap:

And also in parallel with the primary LC circuit. One of the NST terminals goes upwards and connects to the inner end of the primary coil:

The other NST terminal is left with a 1 m cable and the end is connected to a crocodile clip (black), which will later connect with one of the primary capacitor's terminal. The crocodile clip will allow for easy assembly and disassembly of the project:

Then, a piece of cable is also prepared with 2 crocodile clips (red), one at each end, to connect between the capacitor to the outside of the primary coil (somewhere between turn 9 and 10 as previously calculated):

The bottom terminal of the secondary coil was connected together with the discharge rod and the earth connector of the NST. A 10 m cable was also added, this would be our connection to the RF ground. At the other end of this cable we placed a small metal rod that would serve as the electrode, this will be stuck directly into the earth:

The building of the project was just the first part. I didn't realize at first that there was a second and harder step, the tuning of the Tesla Coil.

Although calculations were made, there are always differences to what happens in real life, there are too many variables that are harder to control, what this means is that, no matter what results you got in paper, you'll always need to adjust some parameters to optimize the physical results.

In our case it was mostly the distance of the spark gap and the turns on the primary coil. The spark gap would stop firing sometimes, which we then discovered it was because the electrodes were too far apart from each other, so we put them a bit closer. Now the primary coil was based on a try and error approach, we knew from the calculations in which turn we should get the optimal results, so by moving the crocodile clip a bit right or a bit left, it would change the inductance of the coil and ultimately the resonant frequency.

Eventually we got it better, now it would produce discharges into the air without the rod:

Eventually we started trying other things, for example adding a metal rod on top of the toroid:

This rod would make all the sparks to be generated from its end, creating this amazing tree-like plasma discharge:

Here is a short video of the Coil's discharges into the rod:

But of course we wouldn't stop there, one of the funniest and most interesting things to do with a Tesla Coil is to light up fluorescent tubes just by being in the proximity of the Coil. A great example of wireless transmission of energy:

Fortunately we were able to finish the project before Lisbon Mini Maker Faire, so we took it there:

During daylight it was turned off, because there was too much light for the show, but as soon as the night came, the Tesla Coil would start firing:

The following video shows Micael demonstrating the project with the discharge rod:

Still at the Maker Faire, here are 2 friends of mine playing with fluorescent tubes near the Tesla Coil. It kinda looks like a Jedi fight:

There were plenty of visitors interested in the Tesla Coil:

The project even got featured on a technology program for a Portuguese TV channel:

The Tesla Coil was also awarded a prize at Maker Faire, as an outstanding project!

Still, I know that the project can be even more optimised, but that's for another time.

The project even got featured on a technology program for a Portuguese TV channel:

Still, I know that the project can be even more optimised, but that's for another time.

.png)

Hi.

ReplyDeleteI built the same with 10kv 30ma may.

But the spark gap didn't fired at all.

I used an electronic nag.

Is there any problem with electronic may?

What do you mean by electronic nag?

Delete